Ultrasonic gas meter

Over the last 20 years, ultrasonic gas meters have become the measuring instrument of choice for gas volume measurement in custody transfer. The technology owes its broad acceptance among gas transport companies to its superior measuring accuracy, reproducibility, wide measuring range and low maintenance costs.

Ultrasonic gas meters use robust sensors that generate repeatable pulses (amplitude and frequency). They also include high-speed electronics, complete with a precise timer for detection, resolution and timing of the transmission/reception of ultrasonic pulses with sufficient time domain resolution. The sensor and electronics configuration of the meter allows high pulse transmission rates. The signal propagation time measurement provides a fast integration of the gas flow velocity so that precise readings can be recorded every second.

The most important development in ultrasonic technology in recent years was the multi-path meter, which determines the average of the axial velocity components over the cross-section of a closed pipe. The design and performance of ultrasonic gas meters are defined in international standards, e.g. ISO 17089 and AGA 9. Ultrasonic gas meters are the technology of choice for custody transfer metering and are approved by MID, Measurement Canada and other national approval bodies.

Ultrasonic gas meter

RSM 200

RSM 200

- MID approval

- In the version with EVC the digital pressure and temperature sensor are included

- Path ultrasonic meter with integrated flow straightener

- Cost-optimized, compact design

- Measuring range 1:100 min, up to 1:160 depending on device size

USM GT400

ultrasonic gas meter

- Optimum stability against pre-interference due to 6 direct measuring paths

- High flow velocity (up to 40 m/s)

- Fully encapsulated, robust and dirt-repellent titanium sensors

- MID approved by the PTB

Proven six-path technology of ultrasonic gas meters

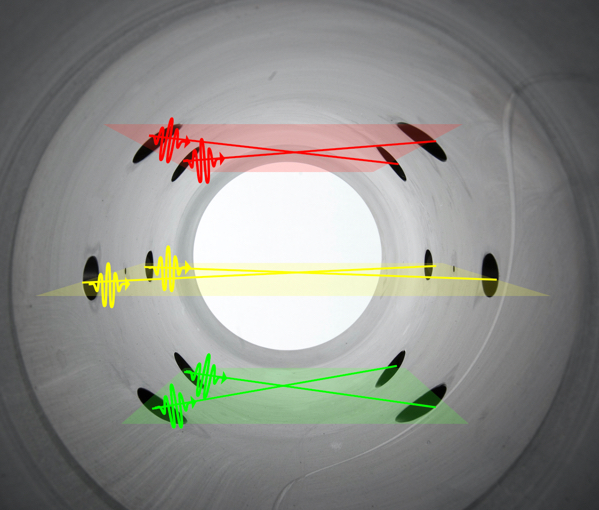

Thanks to their direct path technology with six measuring paths on three levels, our ultrasonic gas meters have stability in the event of flow disturbances. The paths are X-shaped in horizontal planes: a central plane and two geometrically symmetrical secondary planes (top and bottom). This arrangement allows the measurement of turbulences, cross flows and asymmetries as well as a transparent weighting of the path velocities using the Gauss--Chebyshov profile model for compressible fluids. It offers significant advantages especially in those urban gas network applications where limited space for piping and installations can affect meter operation.

Field-proven electronics

The ultrasonic gas meter includes electronics that extend the operating time of the meter system in installations around the world. The electronics optimize the gas meter's internal diagnostic function, sound and flow velocity calculations, signal processing, data storage, interface to flow computers, gas chromatographs or process gas chromatographs and SCADA systems, as well as diagnostic tools for the service engineer.

Plug & Play sensor design

The heart of the ultrasonic gas meter is its sensors, which send and receive sound waves or acoustic pulses. They are configured in such a way that they can be easily replaced on site and under pressure (plug & play). The transit time difference between pairs of sensors is the most important aspect of meter operation. In the GT400, all path-specific measurements are processed internally by the electronics. The Exd sensor from RMG consists of fully encapsulated piezoelectric crystals in a dirt-resistant titanium housing. The sensor operates at standard frequencies of 120 or 200 kHz. The temperature range goes from -40°C to +80°C (-40°F to 176°F) and the pressure range from 1 bar to 300 bar (14.5 psi to 4351 psi). Large measuring ranges (>120:1) with correspondingly high flow velocities up to 40 m/s (131 ft/s) are also possible.

Signal detection and signal evaluation

Our GT400 ultrasonic gas meter uses numerous criteria to validate the pulses without compromising the high signal rates (pulses per second), and the signal detection must display the same measured value reliably and reproducibly, even if there is interference. These can be operational disturbances, which are usually caused by loud noises in the pipeline, e.g. caused by controllers or partially opened valves, and thus influence the signal detection and evaluation. Other disturbances can be of an electromagnetic or flow-related nature. The GT400 ultrasonic gas meter compensates for these disturbances and determines the correct measured values.

Optimized interference immunity

In a gas pipe system, noise from pipe configurations, valves, pressure regulators and nozzle flows can affect the performance of certain ultrasonic gas meters. RMG has solved this problem by combining MID-approved signal detection with the proven Exd sensor design. This has allowed the signal amplitude to be increased for a high signal-to-noise ratio (SRV) compared to conventional intrinsically safe sensors. Noise at ultrasonic frequencies has only a marginal influence on the measurements of ultrasonic gas meters.

Intelligent diagnostic technology of our ultrasonic gas meters

One of the main advantages of ultrasonic gas meters compared to all other flow measurement techniques is the availability of diagnostic information, which does not only include pulses or signals in relation to the gas volume. RMG offers the Windows™-based RMGViewUSM software for parameterization and diagnostics as an interface for robust monitoring of the operating status. This application is easy to use and all data is systematically displayed in clearly arranged tables. In addition, selected measured values and parameters can be summarized in user-defined tables. The RMGViewUSM software monitors the condition of the ultrasonic gas meters and issues warning messages if problems are expected.

In addition, the gas process is monitored and an alarm is issued if there are any faults, e.g. pipeline contamination, blockages or liquids in the gas flow. Finally, the software monitors calculated measurement inaccuracies and issues an alarm if necessary.

In addition, the gas process is monitored and an alarm is issued if there are any faults, e.g. pipeline contamination, blockages or liquids in the gas flow. Finally, the software monitors calculated measurement inaccuracies and issues an alarm if necessary.

Advantages of our ultrasonic gas meters for your company

The ultrasonic gas meters help to reduce the cost of implementing a modern gas measurement system. This is partly due to the possibility of using smaller meters with a higher flow rate and a larger measuring range. In addition, the X-shaped path arrangement of the GT400 ultrasonic gas meter enables extremely precise measurement without long running-in distances. In many cases, a single ultrasonic gas meter can replace two turbine meters that are used in parallel small and main load rails. In addition, the optimized signal detection of the ultrasonic gas meter eliminates the need for an expensive infrastructure for noise attenuation.

Reduced operating costs

Our ultrasonic gas meters are the optimal solution when it comes to reducing maintenance and repair costs at measuring points. It is a purely electronic device, without any moving parts. The operation of the meter is not directly affected by impurities on the pipe wall. The extremely reliable sensors, which have been successfully used in practice since 1999 and are being continuously developed, limit the dispatch of service personnel to a minimum.

Optimized uptime

Operators of natural gas plants can use ultrasonic technology to prevent unplanned shutdowns and production losses. The robust meter sensors offer two-path redundancy (MID approval) for higher reliability in extreme situations. The titanium sensor surface is dirt-repellent, so there is no need to interrupt the measurement for cleaning. In extreme cases, the plug & play design of the sensors reduces the time needed to replace the sensors.

Reduced risk

RMG's experienced experts work with the customer on all aspects of product and application planning for installations with ultrasonic gas meters. We understand the critical importance of service and support throughout the project life cycle. Our trained and certified service engineers offer support during initial commissioning and on-site service.