Volume corrector

Reliable volume correctors from RMG enable you to perform efficient and precise conversions.

Find the right volume corrector for your project

RMG volume correctors are used to calculate standard volumes using various correction methods. Our range of flow computers enables you to improve temperature and pressure transmissions. Installation on turbine meters is also possible.

A volume corrector receives the measured gas volume from a meter and converts it to the standard state. It is necessary because the flow meters for the gas (including turbine, ultrasonic, rotary piston or bellows meters) can only record the operating volume of the gas flow. This operating volume is the volume that can be determined at the measuring point under the existing temperature and pressure conditions. However, for exact billing of gas consumption, comparability with the standard state is required by law. For this reason, the legislator also prescribes the volume corrector if gas above a certain pressure flows in the gas pipe.

Flow Computer

RFC 7

RFC 7

This state-of-the-art device, with its advanced features, meets all operational needs. A new generation of flow computers that sets unprecedented standards in innovation and efficiency.

- Multi-Language support

- Intelligent Search engine

- Increased processor speed

- IP based remote viewer

- Feather touch display

- Advanced Cyber security features

Flow Computer

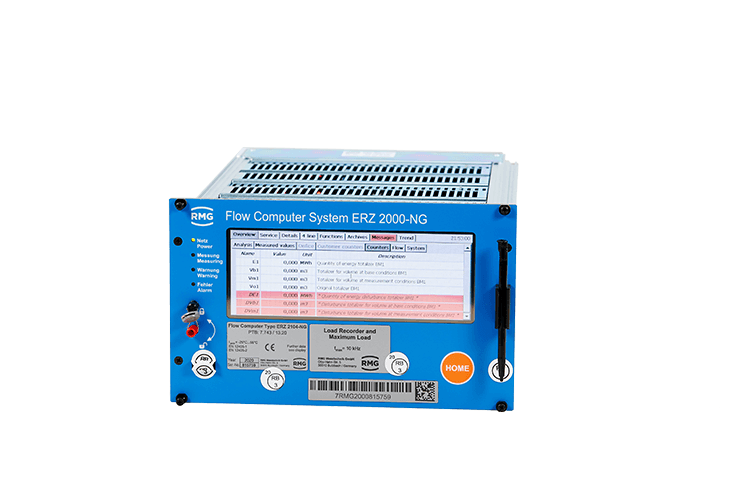

ERZ 2000-NG

ERZ 2000-NG

In addition to the common calculation methods, the most commonly used communication protocols are also supported by the device:

- Modbus (RTU, ASCII)

- Modbus TCP

- Instance-F

- DSfG A and B

- RMGBus

- THEREOF

- HART

Flow Computer

ERZ 2000-DI

ERZ 2000-DI

Use in custody transfer or operational metering applications in combination with different types of gas meters:

- Turbine meter

- Ultrasonic meter

- Vortex meter

- Rotary piston meter

Compact volume corrector

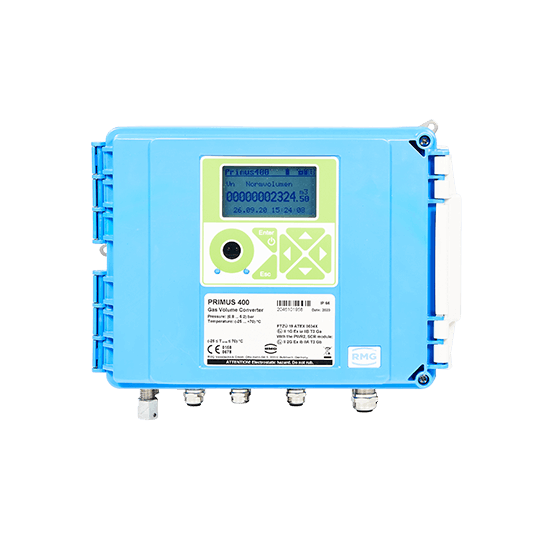

Primus 400

Primus 400

Calculation of the compressibility number (K number) according to different methods:

- MKV Parameters (L-Gas/ H-Gas)

- AGA NX-19 mod

- AGA8-G1/ G2

- SGERG-88

- AGA8-92DC

- as a constant

Compact volume corrector

EC 900

EC 900

Compact volume corrector with many communication possibilities with a meter:

- 1 volume input as LF input (Reed/Wiegand)

- HF input (Reed/Namur/Wiegand)

- 1 volume input for encoder

- 2 or 4 status inputs

How does the volume corrector work in principle?

The measuring device determines three or four values with its sensors:

From these values, it determines the standard volume using one of the various calculation methods. It can save the calculated values at different intervals and forward them via different interfaces (wired, optical, wireless). The volume flow is determined by the volume corrector under standard gas conditions. These are the conditions that usually prevail at the measuring point in terms of temperature and pressure. The quantity determined after the calculation (standard volume) is given in standard cubic meters. This quantity can be multiplied by the specific calorific value of the gas. This can also be used to determine the energy in kWh/MJ, which is particularly important for hydrogen energy measurement in billing-relevant applications.

- gas pressure

- gas temperature

- Operating volume

- Gas analysis (only for large applications with available PGC)

From these values, it determines the standard volume using one of the various calculation methods. It can save the calculated values at different intervals and forward them via different interfaces (wired, optical, wireless). The volume flow is determined by the volume corrector under standard gas conditions. These are the conditions that usually prevail at the measuring point in terms of temperature and pressure. The quantity determined after the calculation (standard volume) is given in standard cubic meters. This quantity can be multiplied by the specific calorific value of the gas. This can also be used to determine the energy in kWh/MJ, which is particularly important for hydrogen energy measurement in billing-relevant applications.

What is the volume flow?

The volume flow is in principle the flow rate. The physical quantity of the volume flow is part of fluid mechanics and indicates the volume of the medium per time period that is transported through a defined cross-section. The medium can be a gas or a liquid (more rarely a powder). The volume flow is specified in the internationally standardized SI unit m³/s. Because gas measurement generally involves large volumes, m³/h is usually used.

A gas volume flow depends on the pressure and temperature of the gas. Both values are not constant in pipeline networks or in industrial processes. They change repeatedly due to various influences, including the ambient temperature or the pressure with which the supplier feeds the gas pipeline. For this reason there must be a standard volume flow (standard flow rate) to which the measured volume flow is converted in order to be able to bill the gas correctly. The volume corrector carries out this conversion. It converts the measured volume during a certain period of time to the standard volume at defined pressure and temperature values.

A gas volume flow depends on the pressure and temperature of the gas. Both values are not constant in pipeline networks or in industrial processes. They change repeatedly due to various influences, including the ambient temperature or the pressure with which the supplier feeds the gas pipeline. For this reason there must be a standard volume flow (standard flow rate) to which the measured volume flow is converted in order to be able to bill the gas correctly. The volume corrector carries out this conversion. It converts the measured volume during a certain period of time to the standard volume at defined pressure and temperature values.

Design of volume correctors

Volume correctors are used in different zones and for different requirements. The Ex zones (possible gas escape zones) in the vicinity of a gas connection or meter are numbered 0, 1, 2, with the digits designating hazard classes according to the potentially more or less explosive atmosphere in the zone concerned. There are, for example, compact battery-powered volume correctors for Ex zone 1 with data storage functions and optional manual or automated readout options. In addition, there are volume correctors for the calorific value that immediately calculate the energy contained in the volume flow of the gas.

Volume correctors for Ex zone 1, in which an explosive mixture can occur during normal operation, are installed on the gas meter. This is also possible for devices for Ex zone 2, which is defined as being non-hazardous: In this case, an explosive mixture should never or at most very rarely escape during normal operation and then only very briefly.

Volume correctors for Ex zone 1, in which an explosive mixture can occur during normal operation, are installed on the gas meter. This is also possible for devices for Ex zone 2, which is defined as being non-hazardous: In this case, an explosive mixture should never or at most very rarely escape during normal operation and then only very briefly.

Use of the volume corrector

The volume corrector is used differently in different areas, e.g. in the compact device area directly at the gas meter, but in large gas measurement in a control cabinet.

Do you have any questions about:

Volume Corrector

Please contact us if you have any questions or need help. Our employees are always there for you.