Gas meter

RMG gas meters are used by companies all over the world for precise measurement of natural gas volumes.

Gas meters for natural gas, biogas and industrial gases

Gas meters and gas measurement systems from RMG stand for maximum precision and reliability. Whether natural gas meters, turbine meters or ultrasonic gas meters, our solutions accurately record the volume flow and ensure precise gas measurement.

Our RMG gas meters are optimized for fiscal and non-fiscal measurements. They are weatherproof and explosion-proof and can be used flexibly for horizontal and vertical gas flows. With RMG, you measure exactly what counts for your application. As an experienced gas meter manufacturer, we develop solutions for gas networks, industrial companies and energy suppliers. Our customers are the leading operators of gas transmission or distribution networks as well as industrial users.

There are two proven measuring principles to choose from. The ultrasonic gas meter offers high-precision, custody transfer metering. The turbine meter offers a cost-efficient solution for internal applications. Both versions enable reliable process control.

In addition to natural gas, biogas, industrial gases and hydrogen can also be measured reliably. Our devices are H2-ready and meet all relevant safety standards. The test bench for gas meters guarantees precise calibration. Put your trust in RMG when it comes to high-precision gas measurement.

There are two proven measuring principles to choose from. The ultrasonic gas meter offers high-precision, custody transfer metering. The turbine meter offers a cost-efficient solution for internal applications. Both versions enable reliable process control.

In addition to natural gas, biogas, industrial gases and hydrogen can also be measured reliably. Our devices are H2-ready and meet all relevant safety standards. The test bench for gas meters guarantees precise calibration. Put your trust in RMG when it comes to high-precision gas measurement.

Ultrasonic gas meter

RSM 200

RSM 200

- MID approval

- In the version with EVC the digital pressure and temperature sensor are included

- Path ultrasonic meter with integrated flow straightener

- Cost-optimized, compact design

- Measuring range 1:100 min, up to 1:160 depending on device size

USM GT400

Ultrasonic Gas Meter

Ultrasonic Gas Meter

- MID approved by the PTB

- 6 direct measuring paths, arranged as X in 3 planes

- High flow velocity (up to 40 m/s)

- Fully encapsulated, robust and dirt-repellent titanium sensors

Turbine wheel gas meter

TRZ 03

TRZ 03

- MID approved by NMI

- Durable, low maintenance and robust

- Meets or exceeds the requirements of DIN/EN 12261

- Optional serial data transmission via encoder

- Horizontal or vertical mounting position possible

Gas Volumeter

TRZ 03 K

- Turbine wheel gas meter in shortened design

- Very good reproducibility

- Durable, low maintenance and robust

- Horizontal or vertical mounting position possible

- Special versions for corrosive gases (e.g. raw biogas)

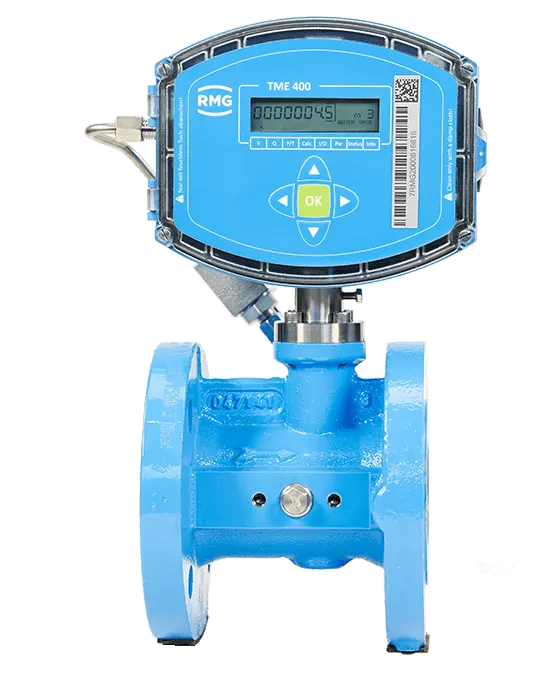

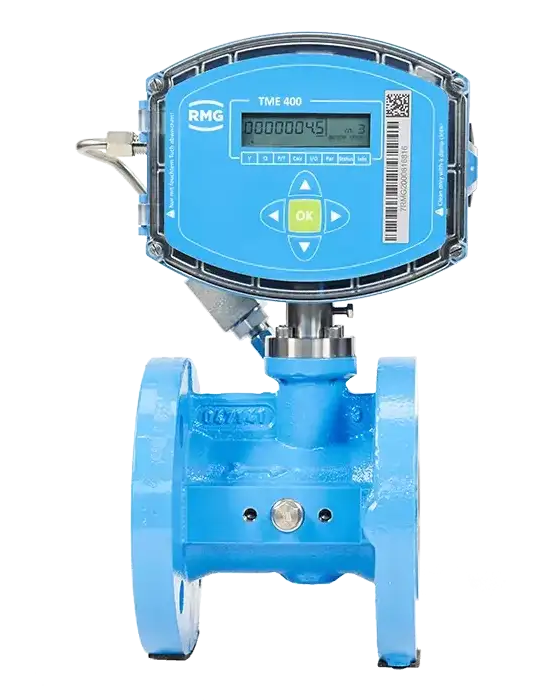

Electronic Volumeter

TME 400-VM

TME 400-VM

- Turbine wheel gas meter with electronic totalizer

- Short design

- Display of volume and flow rate

- Battery operation (6 years), external supply optional

- Serial interface (Modbus)

Electronic Volumeter

TME 400-VC

TME 400-VC

- Turbine wheel gas meter with electronic totalizer and integrated volume corrector

- Short design

- Integrated temperature and pressure measurement

- No installation effort for pressure and temperature measurement

- Display of pressure, temperature, volume and flow rate, each in operating and standard status

Turbine wheel gas meter

TME 400-VMF/VCF

TME 400-VMF/VCF

- MID approved by NMI

- Overall length 3xDN according to DIN/EN 12261

- Complies with DIN/EN 12405 for volume correctors (VCF)

- Integrated temperature and pressure measurement

- Display of pressure, temperature, volume and flow rate, each in operating and standard status

- Integrated measurement archives

Gas meter for volume measurement

Gas meters are made for precise volume flow measurement in industry and trade. They record gas consumption for billing purposes or in processes where the precise determination of gas flows is crucial. Measurement is complex, as gases expand or contract depending on pressure and temperature.

Modern RMG gas meters record the operating volume precisely. Volume conversion makes it possible to calculate the actual standard volume. This technology is particularly important for gas billing or the control of industrial processes. Turbine gas meters, ultrasonic gas meters and gas volume meters are the optimum choice depending on the application.

In the domestic sector, diaphragm gas meters dominate, while commercial enterprises often use rotary gas meters. Calibratable systems are available for high-precision applications. A test bench for gas meters ensures the accuracy of the measuring devices.

As an experienced gas meter manufacturer, RMG offers solutions for natural gas, biogas and industrial gases. Our ultrasonic gas meters and turbine meters meet the highest standards and are reliable for custody transfer metering. You can rely on our many years of experience and certified quality.

Modern RMG gas meters record the operating volume precisely. Volume conversion makes it possible to calculate the actual standard volume. This technology is particularly important for gas billing or the control of industrial processes. Turbine gas meters, ultrasonic gas meters and gas volume meters are the optimum choice depending on the application.

In the domestic sector, diaphragm gas meters dominate, while commercial enterprises often use rotary gas meters. Calibratable systems are available for high-precision applications. A test bench for gas meters ensures the accuracy of the measuring devices.

As an experienced gas meter manufacturer, RMG offers solutions for natural gas, biogas and industrial gases. Our ultrasonic gas meters and turbine meters meet the highest standards and are reliable for custody transfer metering. You can rely on our many years of experience and certified quality.

Gas meters for pipeline network operators and industrial customers

Gas meters from RMG are the first choice for pipeline network operators and industrial customers. Depending on the volume flow and pressure range, turbine gas meters or ultrasonic gas meters are used. These are approved for custody transfer metering, but there are also versions for internal measurements.

As an experienced gas meter manufacturer, RMG offers solutions for natural gas, biogas and gas mixtures containing hydrogen. Our devices have been tested and approved for safe use. The test bench for ultrasonic gas meters ensures maximum precision. Put your trust in RMG for reliable gas measurement in industry and network operation.

As an experienced gas meter manufacturer, RMG offers solutions for natural gas, biogas and gas mixtures containing hydrogen. Our devices have been tested and approved for safe use. The test bench for ultrasonic gas meters ensures maximum precision. Put your trust in RMG for reliable gas measurement in industry and network operation.

Ultrasonic gas meter

Gas meters with ultrasonic technology set new standards in precise gas measurement. The ultrasonic gas meter measures the flow rate based on the transit time of ultrasonic pulses. These are guided through the gas by transducers and their transit time difference determines the volume flow.

Thanks to several measuring paths, the ultrasonic gas meter records the complete flow profile. It works without mechanical components, causes no pressure loss and delivers highly precise measured values. It has been the leading technology in large gas measurement for over 20 years.

As an experienced ultrasonic gas meter manufacturer, RMG offers solutions for natural gas, biogas and high-pressure applications up to 300 bar. Our devices are suitable for pipeline network operators and industry. Put your trust in RMG when it comes to reliable devices for gas measurement.

Thanks to several measuring paths, the ultrasonic gas meter records the complete flow profile. It works without mechanical components, causes no pressure loss and delivers highly precise measured values. It has been the leading technology in large gas measurement for over 20 years.

As an experienced ultrasonic gas meter manufacturer, RMG offers solutions for natural gas, biogas and high-pressure applications up to 300 bar. Our devices are suitable for pipeline network operators and industry. Put your trust in RMG when it comes to reliable devices for gas measurement.

Turbine wheel gas meter

Gas meters with turbine wheel technology offer precise measurements for custody transfer applications. Incoming gas sets the turbine wheel in motion. The speed corresponds exactly to the flow rate.

The flow guide body ensures a uniform flow and maximum measuring accuracy. Classic turbine meters transfer the revolutions mechanically to a roller counter. Modern models use electronic totalizers for even more accurate measurement.

As an experienced gas meter manufacturer, RMG offers durable and reliable systems. Our devices for gas measurement impress with their high reproducibility and long-term stability. They are used as reference standards in high-pressure gas meter test benches. Rely on RMG for precise natural gas meters and industrial applications.

The flow guide body ensures a uniform flow and maximum measuring accuracy. Classic turbine meters transfer the revolutions mechanically to a roller counter. Modern models use electronic totalizers for even more accurate measurement.

As an experienced gas meter manufacturer, RMG offers durable and reliable systems. Our devices for gas measurement impress with their high reproducibility and long-term stability. They are used as reference standards in high-pressure gas meter test benches. Rely on RMG for precise natural gas meters and industrial applications.

Gas Volumeter

Gas meters in the form of a gas volumeter are special measuring devices for volumes that are used in process technology. They are based on the proven technology of turbine wheel gas meters, but are optimized for internal measurements.

These volumeters provide precise, reproducible values and enable reliable control of industrial processes. Due to their simplified design, they are cost-efficient, but have a slightly higher measurement uncertainty.

As an experienced gas meter manufacturer, RMG offers robust and durable solutions for measuring volumetric flow. Our gas measurement devices deliver high quality for process measurements in industry. Trust RMG for reliable and precise gas meters.

These volumeters provide precise, reproducible values and enable reliable control of industrial processes. Due to their simplified design, they are cost-efficient, but have a slightly higher measurement uncertainty.

As an experienced gas meter manufacturer, RMG offers robust and durable solutions for measuring volumetric flow. Our gas measurement devices deliver high quality for process measurements in industry. Trust RMG for reliable and precise gas meters.

Important questions and answers about gas meters

Accurate gas meters are crucial for reliable metering and billing. In this section, we answer important technical aspects relating to gas metering, calibration, maintenance and different types of gas meters. Find out more about functionality, calibration and safety requirements for industry and network operators.

Do you have any questions about:

Gas Meters

Feel free to contact us if you have any questions or need help. Our employees are always there for you.