Gas analysis equipment

Gas analysis devices are used to measure the composition of gases and gas mixtures. They are used in a wide variety of areas, such as gas suppliers, industry and laboratories, municipal utilities, gas plant constructors, gas transport companies and gas storage operators.

Precise measurement of natural gas, biogas and mixed gas

Our gas analyzers provide you with all the components of the composition of natural gas, biogas, gas from Power-2-Gas applications and their mixed gases. Intelligent data communication gives you access to the information for your integrated networked plant technology. All gas analysis devices reliably determine calorific values, density, the Wobbe index and often include a gas calorimeter for precise determination of the calorific value. See for yourself!

Process gas chromatograph

RGC 717

RGC 717

Gas chromatograph for determining the purity of hydrogen.

- Gas transportation (hydrogen backbone)

- Industrial quality measuring devices for pure hydrogen

- Gas storage for hydrogen caverns

- Electrolyzer/hydrogen production

- Hydrogen entry point

- Hydrogen exit point

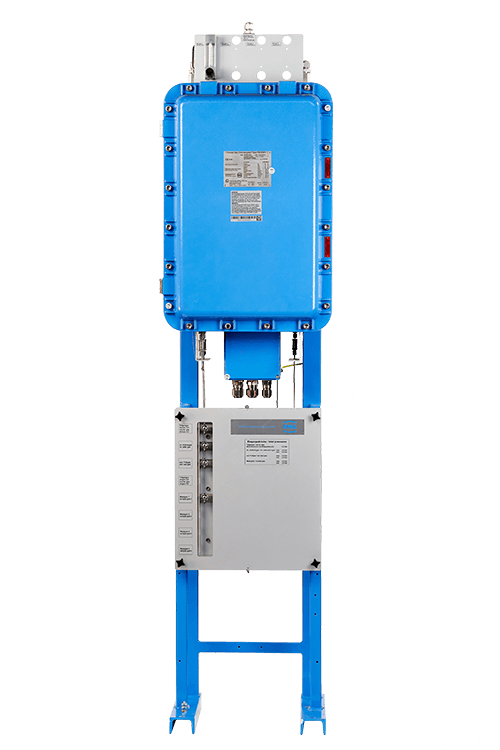

Process gas chromatograph

RGC 704

RGC 704

Gas chromatograph for the measurement of:

- Natural gas

- biogas

- mixed gas

- Hydrogen content up to max. 20 mol%

- Up to 14 components

Process Gas Chromatograph

PGC 9301

PGC 9301

Gas chromatograph for the measurement of:

- Natural gas (11 components

Gas Quality calorimeter

RGQ 5 / RGQ 3

RGQ 5 / RGQ 3

Combustionless measuring method, available in the following versions:

RGQ 511 Extended

These have been developed for different accuracies and gas compositions. Other gas compositions on request.

RGQ 511 Extended

- Viscosity and Thermal Conductivity Detector

- Viscosity, TCD and CO2 Sensor

- Viscosity and TCD Sensor and H2 Detection

- Viscosity, TCD, CO2 Sensor und H2 HW

These have been developed for different accuracies and gas compositions. Other gas compositions on request.

Basic task of the gas analysers

Our gas analyzers determine precisely what is in gas mixtures:

Thanks to the use of state-of-the-art sensor technology and intuitive operating elements, they are easy to operate. At the same time, they guarantee exact analysis results, which guarantees the quality of the processes. Depending on the type of application, gas analyzers are supplied integrated with mixing systems or separately. They can be installed stationary for continuous gas analysis. They measure the concentrations of various gases and are used in a wide range of applications as mentioned above. Industrial applications include the control of gas supply lines in thermoprocessing plants.

For continuous gas analysis, the analysis module is integrated into the gas mixing system. In this way, continuous monitoring of the gas mixture is possible. A further industrial application is the control of the gas for protective and surface refinement in the steel industry, where a high accuracy of the gas mixture is required. Sample analyses with mobile equipment are more in demand in laboratories and in the food and packaging industry.

- the concentrations of the individual components of the gases

- the gas quantity

- the gas quality according to a correlative method

Thanks to the use of state-of-the-art sensor technology and intuitive operating elements, they are easy to operate. At the same time, they guarantee exact analysis results, which guarantees the quality of the processes. Depending on the type of application, gas analyzers are supplied integrated with mixing systems or separately. They can be installed stationary for continuous gas analysis. They measure the concentrations of various gases and are used in a wide range of applications as mentioned above. Industrial applications include the control of gas supply lines in thermoprocessing plants.

For continuous gas analysis, the analysis module is integrated into the gas mixing system. In this way, continuous monitoring of the gas mixture is possible. A further industrial application is the control of the gas for protective and surface refinement in the steel industry, where a high accuracy of the gas mixture is required. Sample analyses with mobile equipment are more in demand in laboratories and in the food and packaging industry.

Components of gas analysis equipment

The technical core of the gas analysis devices is the measuring cell. There are various construction variants, such as measuring cells based on zirconium dioxide, which respond very quickly and last a long time, but require a lot of power and are sensitive. There are also low-cost electrochemical measuring cells that operate without supply voltage, paramagnetic dumbbell measuring cells for long-term stable measuring signals with longer calibration intervals, and low-wear microthermal sensors.

Gas analysis equipment for natural gas analysis for gas suppliers

Practical example for gas analysis

With the latest generation of gas analyzers, gas suppliers can make their analyses even more environmentally friendly. To do this, they use gas analysis devices that use a microthermal sensor in combination with a critical nozzle. They are initiating a generational change in gas mixing stations. In biomethane feed-in stations, the calorific value can be adjusted to the calorific value in the pipe by adding air or butane.

Gas suppliers must monitor the quality of the natural gas. This consists of over 80 % methane, as well as ethane, butane, propane, nitrogen and carbon dioxide. Individual types of natural gas differ, sometimes considerably, in their composition; they contain varying amounts of the individual gases mentioned. However, this is of minor importance for gas applications. In practice, the important parameters have to be determined:

Our gas analysis devices determine these parameters in the natural gas industry and at suppliers such as municipal utilities. A common analytical method is IR spectroscopy (infrared spectroscopy), which enables rapid gas analysis. It operates with infrared radiation of wavelengths 800 nm to 1.0 mm and analyses the energy states in molecules. The analysis is based on the identification of the gas mixture using a reference spectrum. Alternatively, gas chromatography (GC) can be used, whose selectivity is even higher but requires a much longer response time. It is also expensive in terms of equipment and requires a lot of maintenance.

- Calorific value of the gas

- Methane number

- Wobbe-Index (quality determination of fuel gases such as natural and town gas)

Our gas analysis devices determine these parameters in the natural gas industry and at suppliers such as municipal utilities. A common analytical method is IR spectroscopy (infrared spectroscopy), which enables rapid gas analysis. It operates with infrared radiation of wavelengths 800 nm to 1.0 mm and analyses the energy states in molecules. The analysis is based on the identification of the gas mixture using a reference spectrum. Alternatively, gas chromatography (GC) can be used, whose selectivity is even higher but requires a much longer response time. It is also expensive in terms of equipment and requires a lot of maintenance.

When it becomes relevant to calibration law, there is no getting around gas chromatographs

A gas chromatograph analyses the composition of natural gas or upgraded biogas and determines its most important components in mol% proportions. The following quantities are then calculated from these proportions:

Even in the concentrations of hydrogen up to 20 mol%.

The gas chromatograph thus provides the analysis values required for a state or calorific value conversion with calculation of the compressibility number according to GERG 88-S or AGA 8 in a calibratable form. For all versions a PTB type approval or type examination certificate (module B) according to the new measuring and calibration regulations is available.

- Calorific value

- Calorific value

- Standard density

- Density ratio

- Wobbe number (optionally also the methane number)

Even in the concentrations of hydrogen up to 20 mol%.

The gas chromatograph thus provides the analysis values required for a state or calorific value conversion with calculation of the compressibility number according to GERG 88-S or AGA 8 in a calibratable form. For all versions a PTB type approval or type examination certificate (module B) according to the new measuring and calibration regulations is available.

Do you have any questions about:

Gas analysis equipment

Please contact us if you have any questions or need help. Our employees are always there for you.