Gas Volumeter

A gas volumeter measures the volume flow of gas, which is one of several measured variables such as composition, calorific value and the Wobbe index. There are several types of these devices, below we introduce the most commonly used volumeters:

Gas Volumeter

TRZ 03 K

TRZ 03 K

- Turbine meter in shortened design

- High degree of reproducibility

- Mechanical roller counter

- Special versions for corrosive gases

Electronic gas volumeter

TME 400-VC

TME 400-VC

- Turbine meter with electronic totalizer and integrated volume corrector

- Short design

- Integrated temperature and pressure measurement

- Battery operation (6 years), external supply optional

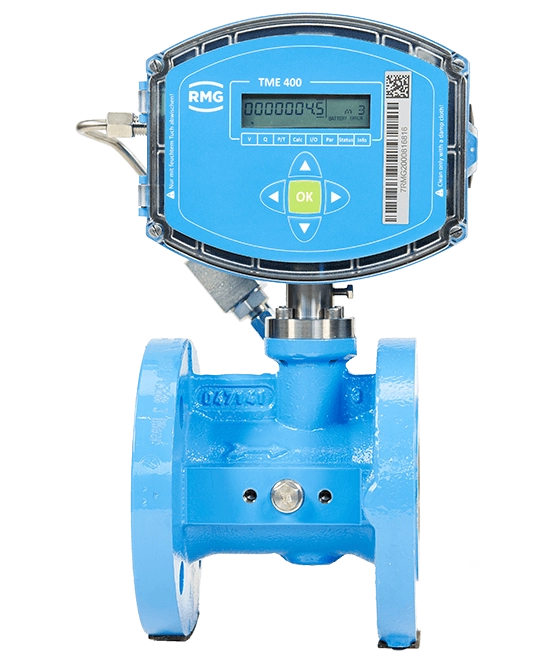

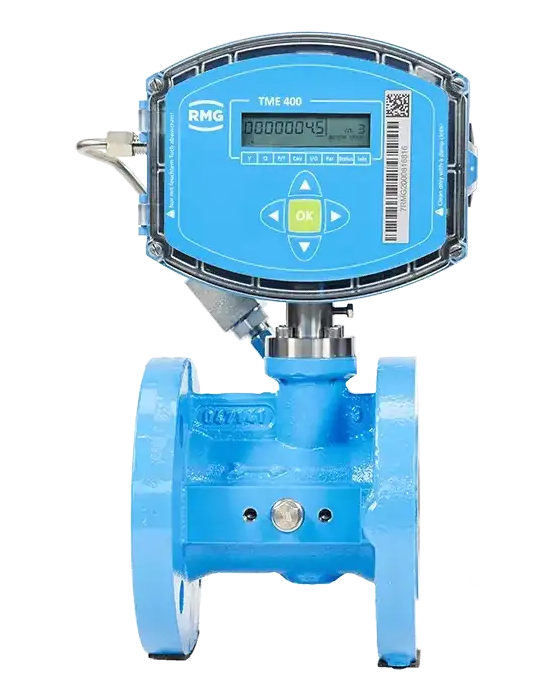

Electronic gas volumeter

TME 400-VM

TME 400-VM

- Turbine meter with electronic totalizer

- Compact design

- Volume and flow rate display

- Battery operation (6 years), external supply optional

- Special versions for corrosive gases

Gas Volumeter with ultrasonic measurement

A gas volume meter can be based on ultrasonic measurement. This is a very modern form of these particular gas meters and has several advantages. For example, there is no mechanical movement in the meter; nor do any parts protrude into the gas flow. This means there is no pressure loss whatsoever. The measurement is very accurate and can be bidirectional. The gas volumeter measures the ultrasonic waves emitted by the gas, which change with its flow velocity.

Gas Volumeter with bellows

The bellows gas meter measures the gas volume flow by displacement measurement. These devices have been around since the end of the 19th century; they are still in use. In a rigid measuring chamber, these chambers are filled with gas, which are divided by diaphragms. During periodic filling, a diaphragm movement is generated which is transmitted to a crankshaft by a joint gear. This in turn controls two gas slides, allowing the gas flow to be directed to a tilting scale, which in turn controls a counter. This counts the filling and emptying of the chambers. By multiplying this number by the chamber volume, the volume flow can be calculated.

Rotary piston meter

When a gas volumeter has to measure the gas flow under high pressure, which is often the case in industry, the rotary displacement meter is well suited. It measures the gas volume with two 8-shaped rotary pistons that are precisely interlocked. They each fill and release ¼ of the regulator volume per half turn of a piston. A magnetic coupling transfers the revolutions to a counter, which relays the signals mechanically or digitally.

The measured operating volume flow is converted to the standard state for comparison purposes. The design of the rotary displacement meter is considered proven and mature. It allows very precise measurements. Modern rotary displacement meters achieve measuring ranges of up to 1:160 as standard.

The measured operating volume flow is converted to the standard state for comparison purposes. The design of the rotary displacement meter is considered proven and mature. It allows very precise measurements. Modern rotary displacement meters achieve measuring ranges of up to 1:160 as standard.

Turbine meter

Turbine meters are used for custody transfer metering. In these meters, incoming gas causes a turbine wheel to rotate. Its revolutions are proportional to the operating volume of the gas flowing through it. The flow measuring body is designed in such a way that a uniform flow profile is obtained within the meter in order to obtain accurate measured values.

Gas volumeter according to the Coriolis principle

The Coriolis principle describes a force (the so-called Coriolis force) that is generated when bodies or fluids move in rotating reference systems if their movement is at an angle (not parallel) to the axis of rotation. The Coriolis force is proportional to the angular velocity of the rotating reference system and the velocity and mass of the body or fluid. This makes it possible to measure, for example, the volume flow of gas.

In Coriolis meters, actuators cause a pipe bend to vibrate. The basis of this pipe bend is its axis of rotation, its oscillating legs complete a pitch circle. These movements are caused by the flow of the gas and can be measured, which makes it possible to measure the gas volume flow. This is done by sensors mounted on the inlet and outlet side of the oscillating system. They measure the difference between different Coriolis forces when the gas flows in and out. The gas volumeter with this operating principle can also be used in hazardous areas and can be used for custody transfer measurements.

Finally, it should be noted that there are other technical principles by which a gas volumeter can measure the volume of gas. In principle, the choice of design is determined by the area of application.

In Coriolis meters, actuators cause a pipe bend to vibrate. The basis of this pipe bend is its axis of rotation, its oscillating legs complete a pitch circle. These movements are caused by the flow of the gas and can be measured, which makes it possible to measure the gas volume flow. This is done by sensors mounted on the inlet and outlet side of the oscillating system. They measure the difference between different Coriolis forces when the gas flows in and out. The gas volumeter with this operating principle can also be used in hazardous areas and can be used for custody transfer measurements.

Finally, it should be noted that there are other technical principles by which a gas volumeter can measure the volume of gas. In principle, the choice of design is determined by the area of application.