Gas burner systems

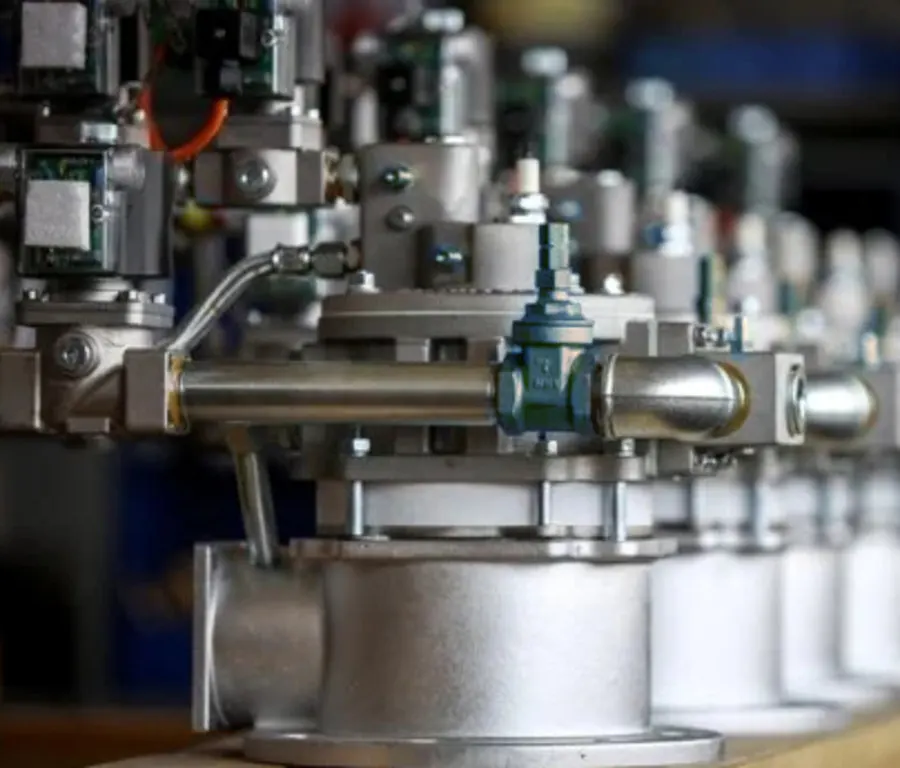

Gas burner systems from RMG efficiently convert gas into heat and enable precise control for a wide range of output requirements. Gas burners up to around 10 MW are usually designed as monobloc burners, where the combustion air fan is integrated directly into the gas burner. Larger burner systems, on the other hand, use external fans and often separate pilot burners for reliable initial ignition at higher outputs.

For smaller burners (< 1 MW), a simple, two-stage control system is usually used, which is activated depending on the steam pressure in the boiler. Continuously controlled, modular gas burner systems are used for higher outputs. Modern energy-efficient gas burner systems rely on an electronic control system that uses separate electrical control valves for gas and air supply instead of a mechanical connection. Gas burner systems with integrated control are optimally adjusted and monitored by a burner control system to ensure safety and efficiency.

The use of the RGQ 5 gas measuring device from RMG Messtechnik optimizes the functionality of gas burner systems. The RGQ 5 is used to determine gas quality by precisely measuring key parameters such as calorific value, methane number and Wobbe index. This data is integrated directly into the burner control system, whereby the fuel-air ratio is dynamically adjusted based on the current gas composition. This minimizes exhaust gas losses, increases efficiency and improves process reliability.

Special gas burners, such as porous burners, work with catalytic converters and thus reduce nitrogen oxide emissions while increasing heat yield. The integration of the RGQ 5 gas analysis device from RMG into such systems enables even more precise control and contributes to the optimization of emission control.

For smaller burners (< 1 MW), a simple, two-stage control system is usually used, which is activated depending on the steam pressure in the boiler. Continuously controlled, modular gas burner systems are used for higher outputs. Modern energy-efficient gas burner systems rely on an electronic control system that uses separate electrical control valves for gas and air supply instead of a mechanical connection. Gas burner systems with integrated control are optimally adjusted and monitored by a burner control system to ensure safety and efficiency.

The use of the RGQ 5 gas measuring device from RMG Messtechnik optimizes the functionality of gas burner systems. The RGQ 5 is used to determine gas quality by precisely measuring key parameters such as calorific value, methane number and Wobbe index. This data is integrated directly into the burner control system, whereby the fuel-air ratio is dynamically adjusted based on the current gas composition. This minimizes exhaust gas losses, increases efficiency and improves process reliability.

Special gas burners, such as porous burners, work with catalytic converters and thus reduce nitrogen oxide emissions while increasing heat yield. The integration of the RGQ 5 gas analysis device from RMG into such systems enables even more precise control and contributes to the optimization of emission control.

Efficient combustion

CE-certified safety

Robust and durable

Modulable power

Low emissions

Versatile application

Gas burner systems for thermal processing plants

Gas burner systems for industrial furnaces are central elements for industrial applications that enable precise control and analysis in gas measurement technology. Systems manufactured by us are operated by gas measuring devices that work with gaseous fuels and comply with strict European and German safety standards.

Gas systems for industry bear a CE mark and must fulfill the installation and connection conditions as well as the requirements for the device category in accordance with DIN EN 437. This classification includes the appropriate type of gas and the required distribution pressures.

The output of gas burner systems with control technology varies depending on the nominal load, which can be set between minimum and maximum heat input. While the nominal load describes the input power, the nominal power refers to the actual output power of the burner systems.

By integrating the RGQ 5 gas measuring device from RMG, the gas quality is analyzed in real time, allowing the modulated control of the burners to be matched even more precisely to the specific composition of the fuel. The calorific value measurement, the determination of the methane number and the Wobbe index enable flexible adaptation to varying gas compositions and ensure efficient and safe combustion.

Industrial combustion technology with gas burners in industrial system solutions range from heat treatment processes to analytical gas measurement techniques. With the support of RMG's RGQ 5, burner controls can be continuously optimized, increasing efficiency and reducing exhaust emissions. This is particularly important in energy-intensive industries to reduce costs and meet environmental standards.

Gas systems for industry bear a CE mark and must fulfill the installation and connection conditions as well as the requirements for the device category in accordance with DIN EN 437. This classification includes the appropriate type of gas and the required distribution pressures.

The output of gas burner systems with control technology varies depending on the nominal load, which can be set between minimum and maximum heat input. While the nominal load describes the input power, the nominal power refers to the actual output power of the burner systems.

By integrating the RGQ 5 gas measuring device from RMG, the gas quality is analyzed in real time, allowing the modulated control of the burners to be matched even more precisely to the specific composition of the fuel. The calorific value measurement, the determination of the methane number and the Wobbe index enable flexible adaptation to varying gas compositions and ensure efficient and safe combustion.

Industrial combustion technology with gas burners in industrial system solutions range from heat treatment processes to analytical gas measurement techniques. With the support of RMG's RGQ 5, burner controls can be continuously optimized, increasing efficiency and reducing exhaust emissions. This is particularly important in energy-intensive industries to reduce costs and meet environmental standards.

Optimized combustion in a gas burner system for maximum energy

Gas burner systems offer a number of advantages that make them an ideal choice for industrial burner technology applications. One of the biggest advantages is their high efficiency. Optimized combustion extracts maximum energy from the fuel, keeping operating costs low. Gas burner systems are also CE-certified and meet all European and German safety requirements, ensuring reliable and safe use.

Technically, low-emission gas burner systems from RMG Messtechnik impress with modulable output settings that enable precise adaptation to different load requirements. Two-stage burner control systems are available for smaller applications, while larger gas burner systems cover a wide output range thanks to continuously adjustable control. State-of-the-art electronic controls ensure an exact fuel-air ratio. This ratio is additionally optimized by superimposed O₂ and CO controls, which increases combustion efficiency and reduces emissions.

Other technical features of RMG appliances include powerful fans with frequency control for an energy-efficient air supply and specially developed burners for minimal nitrogen oxide emissions in process heat technology. As a result, gas technology systems are not only durable and robustly designed for continuous operation, but also offer an environmentally friendly solution for heat treatment and gas measurement technology in a wide range of industrial sectors.

Technically, low-emission gas burner systems from RMG Messtechnik impress with modulable output settings that enable precise adaptation to different load requirements. Two-stage burner control systems are available for smaller applications, while larger gas burner systems cover a wide output range thanks to continuously adjustable control. State-of-the-art electronic controls ensure an exact fuel-air ratio. This ratio is additionally optimized by superimposed O₂ and CO controls, which increases combustion efficiency and reduces emissions.

Other technical features of RMG appliances include powerful fans with frequency control for an energy-efficient air supply and specially developed burners for minimal nitrogen oxide emissions in process heat technology. As a result, gas technology systems are not only durable and robustly designed for continuous operation, but also offer an environmentally friendly solution for heat treatment and gas measurement technology in a wide range of industrial sectors.

Important questions and answers about lathes

A modern gas burner system is at the heart of many thermal processes. It ensures precise, safe and energy-efficient heat supply. In this section, you will find out how a gas burner system works, what advantages it offers and what is important in terms of use, control and safety.

Do you have any questions about our

Gas burner systems

Feel free to contact us if you have any questions or need help. Our staff is always there for you.